POSTHARVEST

Postharvest processes, known in many places as wet processes, start from the collection of coffee cherries. To understand the importance of these processes, it is important to know in detail the parts that make a coffee cherry.

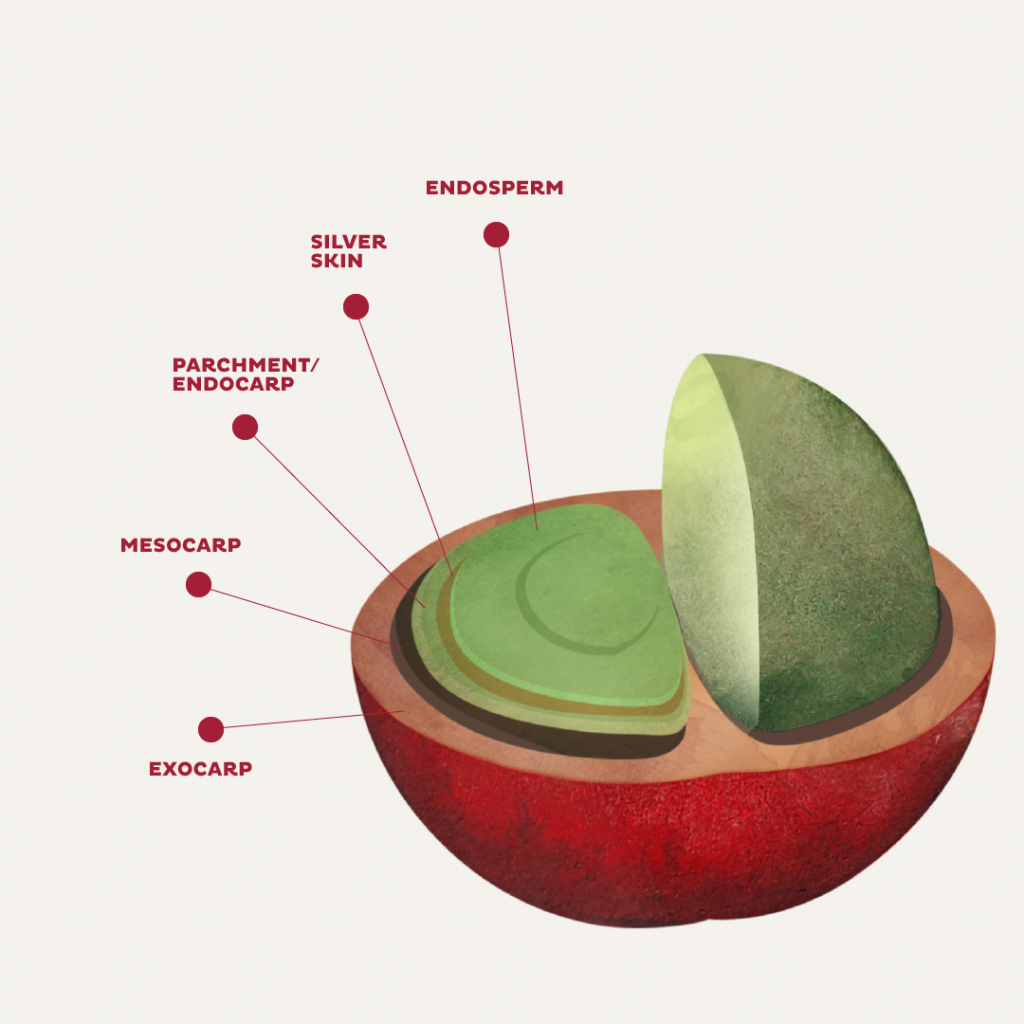

The ripe coffee cherry is a red or yellow fruit. Each cherry has an outer skin (exocarp) that wraps a sweet pulp (mesocarp). Under the pulp are the beans covered by a delicate translucent membrane (Silver Skin) and these membranes wrap the two coffee seeds (endosperm).

Coffee seeds, known as green coffee or gold coffee in certain countries, are those that are roasted for the preparation of the beverage that consumers know.

Post-harvest practices, which vary according to the country, the type of crop and the coffee species, transform the cherry into a dry product, ready for the threshing process.

In other words, they are processes that are used for the separation of the mesocarp from the endocarp. The time that these processes last and the effect that can be generated by the different compounds present in the pulp and mucilage of the coffee in the seed has a clear influence on the final quality of the beverage.

One of the most used processes is the so-called natural dry coffee process. In this post-harvest process, cherries are commonly exposed to the sun for several days to reach a certain degree of humidity in ranges that may vary. One of the effects of this method is the impregnation of the seed with the sugars and other compounds present in the coffee mucilage, which leads to the generation in the final taste of characteristic flavors of the coffees processed by this way.

The wet process of coffee includes de-pulping, fermentation, washing and drying of the grain. De-pulping the cherries, the pulp is quickly removed after harvesting.

In the event that it is delayed for more than 6 hours, the grain, and subsequently the beverage, may present a defect in the cup called fermentation. This defect also occurs when there is the presence of fruits without de-pulping and pulp attached to the parchment or as the increase of the percentage of overripe grain in the harvested coffee.

Subsequently, the mucilage (mesocarp) is removed by fermentation of the grain in fermentation tanks or by mechanical means. Fermentation can last from 12 to 18 hours, depending on the following variables:

- The temperature of the place: the longest fermentation time is required in the coldest areas.

- The height of the coffee dough in the fermentation tank: the higher the coffee layer, the shorter the fermentation time.

- The use of water: dry fermentation is recommended as it accelerates fermentation and allows residual post washed water (honey waters) which should be allowed to leave the outside of the tank.

- The grade of maturity of coffee.

- The quantity of mucilage in the grain.

Fermentation time is a definitive factor in coffee quality, it is necessary to periodically sample coffee dough in the fermentation tank, to determine the optimum point before starting the final grain washing process. If the coffee is over-fermented, stained, loses weight, the almond is corked and the quality is irremediably affected.